Leg springs

Leg springs are one of our specialties. We can look back on decades of experience with them. Normally these products are custom-made according to your specifications. The cylindrical coil springs, which we usually produce from round wires with constant diameter, have a linear torque characteristic. Force or torque is introduced at the legs at the start and end of the springs – they can be adapted to your requirements in many ways. The heat treatment process is temperature-monitored for Eckel Federn.

Finishing

Any type of galvanic surfaces are possible, such as:

pickling, cadmium plating, Delta Seal, Delta Tone, KTL coating, painting, passivating, phosphatisation and oiling, powder coating, chromium coating, gold coating, nickel coating, zinc coating, chromating.

Any type of surface processing can be provided, such as:

electrolytic polishing, slide grinding, annealing and hardening, shot-peening and oiling, sand blasting, vibratory grinding.

Range of services and materials

- Leg springs, torsion springs

- Double leg springs

- Tension springs (with DIN lugs or special lugs)

- Compression springs (cylindrical, conical or multiple conical,

- ends ground or not ground

- cold-set or warm-set)

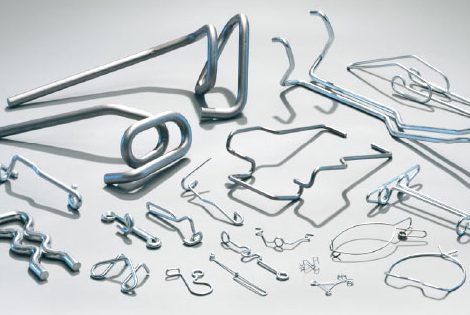

- Bent components, bent wire components, shaped springs (with the most diverse bends)

- Flat springs, leaf springs, moulded parts

- Components

- Circlips

- Spring cotter pins

- Customised springs, special springs

Industries

- Automotive industry

- Armature construction

- Computer industry

- Electrical industry

- Renewable energy / environmental technology

- Agricultural machinery industry

- Lighting industry

- Aerospace and shipping

- Medical and chemical engineering

- Furniture industry

- Food industry

- Commercial vehicles industry

- Toys